With more than 50 years of combined R&D experience, our team is constantly developing technologies with various institutions, from private companies, universities to

national institutions. Our senior researchers engages students and conduct lectures from various universities.

All our applied vehicles go through our state of the art, 7-axis multi-joint 3D scanner. This ensures precise measurements for calculating the right droop and clearance for every

vehicle.

Samples produced are tested by our in-house test drivers, utilizing our 7,600 paved proving ground and 3 precise damper dynamometers.

Neotech is working with the KATECH(Korea Automotive Technology Institute) on high-quality technology development. We are developing various technologies such as

MR(MagneticRheological) damper, electronic control dampers using solenoid valves, and trailing arm using CAE analysis.

With our own in-house MCT & CNC machines, quality control is ensured without the need for outsourced production.

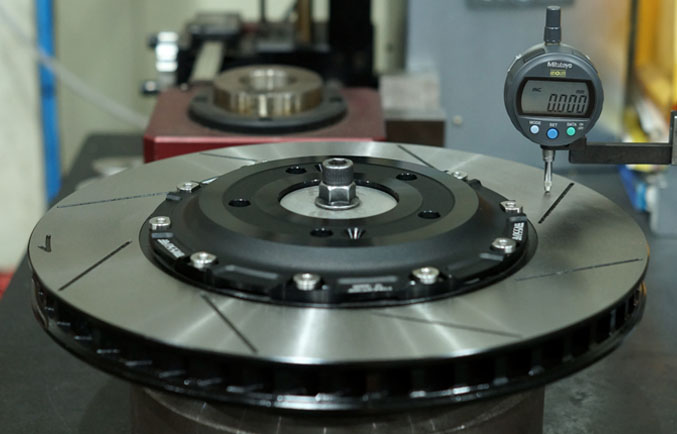

Disc balancing, DTV (Disc Thickness Variation), and Runout inspections are performed on all products and managed in-conjunction to be within

our specifications.

DTV uses a 1/1000mm unit indicator and uses 0.02mm as a QC standard.

Our strict QC standard is the backbone of trust for our customers.

Every damper is dyno tested to be within specifications, before assembly.